Post-Press Infrastructure: Precision, Finishing, and Perfection in Every Detail

At Jaipur Printers, our post-press infrastructure ensures that every print job is finished to perfection, with a focus on precision, quality, and durability. After the printing process, our advanced post-press services handle the essential steps that bring your project to life, from cutting and folding to binding and finishing.

We utilize the latest post-press technology to provide a wide range of finishing options, including lamination, embossing, spot UV, foil stamping, die-cutting, and more. Whether you need perfect binding, saddle stitching, or Wiro O Binding, our post-press services are tailored to ensure your printed materials look professional and polished.

Our expert team ensures the highest level of quality control at every stage, checking for consistency, alignment, and finish quality. With a variety of customized finishing options, we can bring your creative ideas to life and elevate the final product with a premium look and feel.

With our comprehensive post-press infrastructure, we’re able to handle both small-scale projects and high-volume orders with efficiency, delivering superior results every time.

Let Jaipur Printers transform your prints into exceptional products with our cutting-edge post-press services.

Lamination

| Equipment | DESCRIPTION |

|---|---|

| Lamination | 5 Macrobond lamination of Gloss/Matte BOPP films as well as Metallised PET films |

Embellishments

| Equipment | Description |

|---|---|

| Laser Cutting | 1 Machine for high-speed and intricate laser cutting of materials upto 4mm thick |

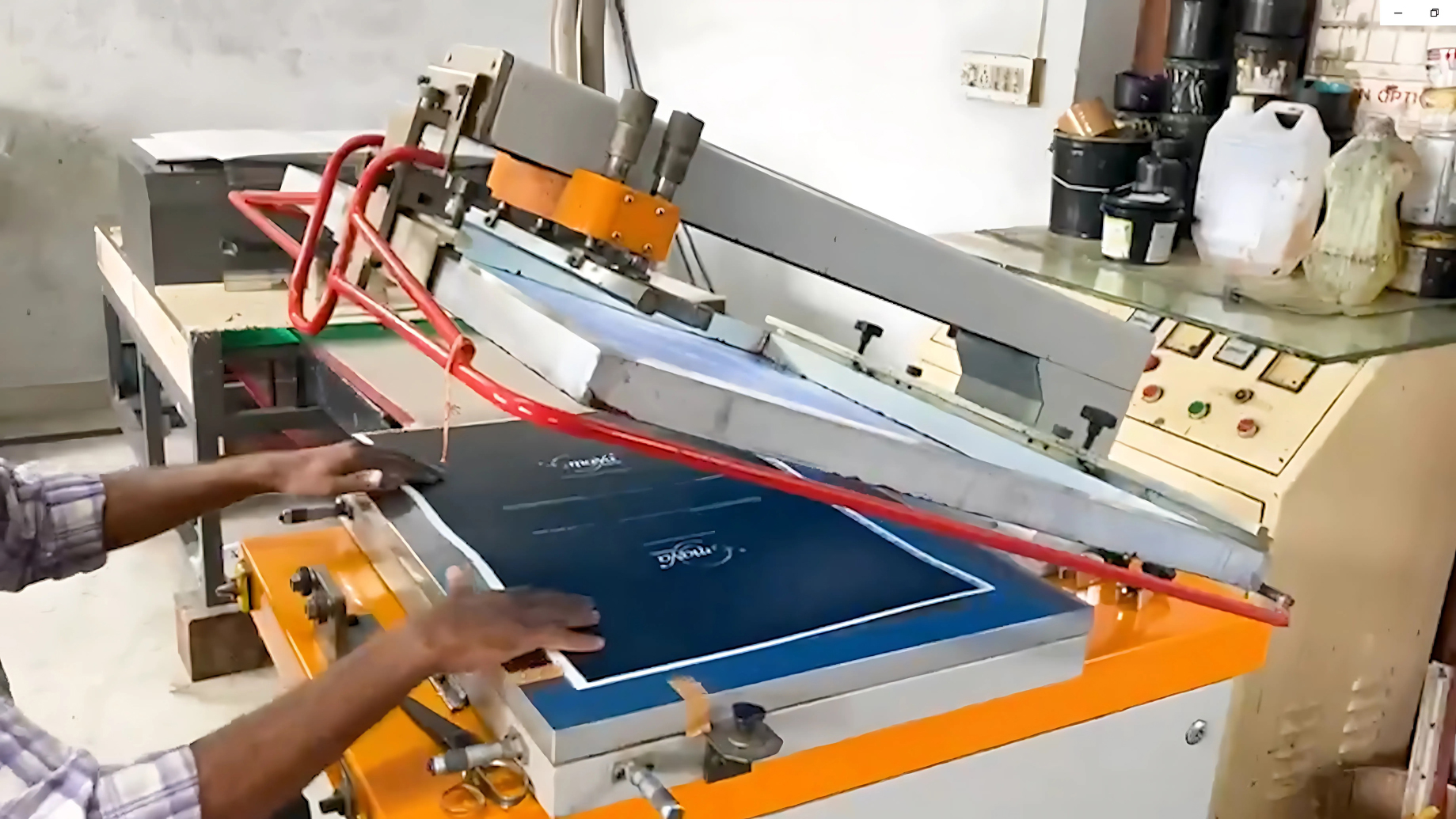

| Spot UV coating | 2 Graphica screen printing machines for spot application of gloss, matte, raised and textured UV finishes |

| Hot Foiling | 2 foiling machines |

| Die Cutting | 2 Die Cutting with Hot Foil Stamping Machines machines |

| Edge Gilding | Gilding of edges of books, thick cards, etc., with metallic foils |

Binding

| Equipment | Description |

|---|---|

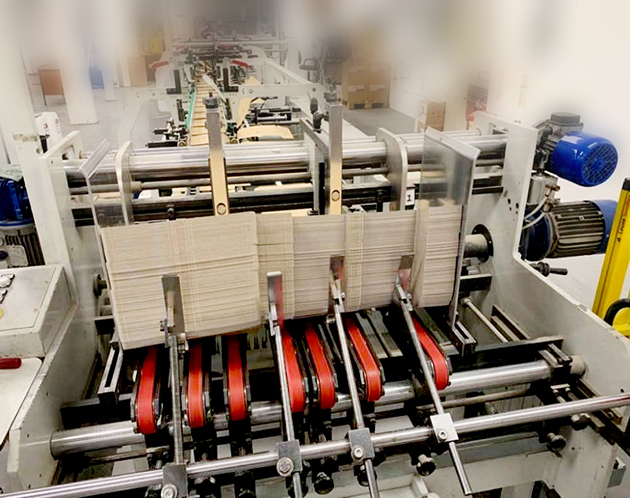

| Folding Machines | 1 folding machines from Wellbound folding capabilities |

| Saddle-stitching (Centre-pinning) | 1 Muller (Martini) pinning and three-knife trimming machines with up to 7 form gathering stations |

| Section-sewing | 2 automatic section-sewing (Smyth-sewing) machines One Italy and One Indian. |

| Perfect Binder | 2 auto-perfect binding machines from Kolbus (17-clamp) and Wellbound (1-clamp), PUR Binding Machine |

| Case-making & Casing-in | Hardcase book making machinery from Memory. Also used for making cases for rigid fliptop boxes |

| Wire-O Sealing | 4 Manual wire-o mounting and sealing machine from Renz (Germany) |

| Wire-O & Spiral hole punching | 4 Semi Automatic machines |

Other Equipments

| Equipment | Description |

|---|---|

| Cutting Machines Programmable | 1 fully programmable cutting machines from Itoh (Japan), and 2 Sudarshan (India) |

| Collators | 2 Auto-collators for collating sheets in sequence & 2 signature collator for sequencing folded forms |

| Back to Back Pasting Machine | 2 Back to Back Pasting Machine |

The Complete Print Solution

Seamless Excellence from the First Draft to the Final Product.

On-Time, Every Time

Your Deadlines, Our Commitment: Reliability in Every Delivery.

State-of-the-Art Craftsmanship

Pioneering the Future of Print with Cutting-Edge Technology and Infrastructure.